*Terms and Conditions Applied:

- PRIMA will only measure combustion efficiency of single boiler and give report for FREE.

- If multiple boilers present at the company, except the first one all others will be chargeable.

- All Travelling and Lodging expenses to be born by the customer

Bhavin Panchal - 7th July 2022

3 mistakes that can be avoided to prevent accidents in Plant using Safety Gas measuring Instruments

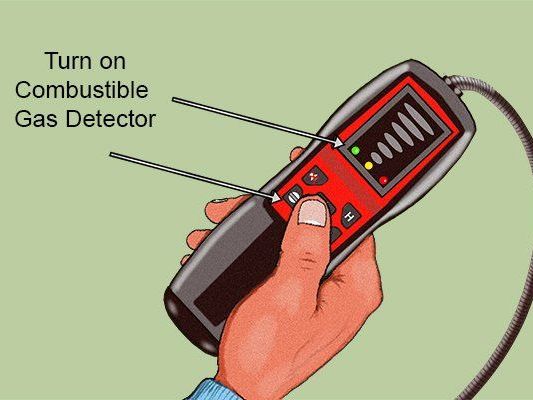

The gas measuring instruments are installed at various locations in a plant i.e., safety gas leakage monitoring, confined space, area surveillance, etc.

A lot of the things are dependent on the measurement of the safety gas detectors.

The safety gas detectors are used to save assets and valuable resources, Occupational safety, and are just not merely a requirement of a regulatory or statutory body.

The major accidents happen related to the Safety gas monitoring system due to several reasons some of which are listed below. We have summarized the most common 3 mistakes to prevent accidents at the workplace having potential hazards due to Toxic or combustible gas.

Lack of Awareness of the functionality of the gas detection system to the working staff.

Ignorance of regular maintenance of gas detection system.

Unreliable Calibration results performed by an incompetent engineer.

Do your safety monitoring instruments are calibrated by OEM?

Does OEM have expertise in the calibration of gas detectors?

Does OEM have the required CRM (Certified Reference materials) for calibration?

Does OEM have a competent workforce to calibrate instruments?

What is the level of impartiality while calibration by OEM?

We are having India’s First Accredited calibration laboratory as per ISO/IEC 17025 standard having the scope of accreditation of toxic gases as well as hydrocarbon gases. If you are concerned about the safety of the workplace and the authentic calibration of gas monitoring instruments you may contact us.